CO₂ as a refrigerant – five potential hazards of R-744

In the fifth post in this CO2 as a Refrigerant blog series, I will overview the potential hazards associated with handling systems in which R-744 is used.

Although R-744 is non-flammable, its high pressures, toxicity in high concentrations and potential for dry ice formation must be considered when applying and handling it. The following list summarizes its top five potential hazards and provides guidance on reducing them.

- Asphyxiation

R-744 is odorless, heavier than air and an asphyxiant. The occupational exposure limit (OEL) of R-744 is lower than non-toxic A1 hydrofluorocarbons (HFCs) because of its potential toxicity. Compare its OEL to other HFCs and natural refrigerants:

- R-744 — OEL with a time weighted average of 8 hours is 5,000 parts per million (ppm)

- R-404A (HFC) — OEL with a time weighted average of 8 hours is 1,000 ppm

- R-717 (ammonia) — OEL with a time weighted average of 8 hours is 25 ppm

Note: The practical limit is defined in ASHRAE 15-2019 but may vary in regional regulations.

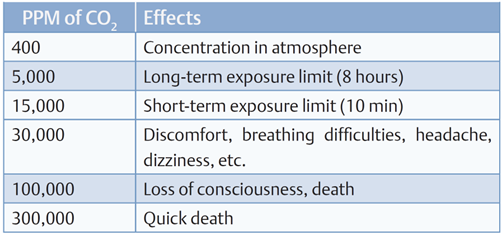

Consider the effect of R-744 at various concentrations in the air.

Table 1: Effects of CO2 (R-744) at various concentrations in the air

Because R-744 leaks could result in a concentration exceeding the practical limit in an enclosed occupied space (i.e., machine or cold room), precautions must be taken to prevent asphyxiation. These include the use of permanent leak detection, which activates an alarm in the event of a leak.

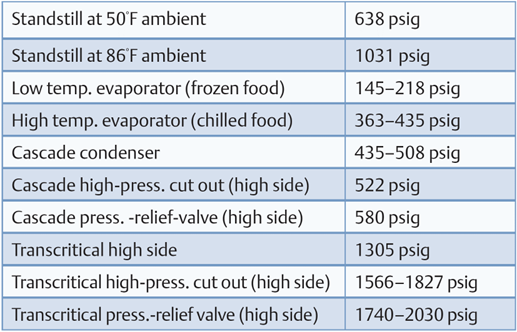

- High system operating pressures

R-744 systems operate at significantly higher pressures compared to legacy HFC systems, especially when ambient temperatures cause a system to operate above its critical point (i.e., supercritical mode). As a result, system components, pipe work, tools and equipment must be rated to safely operate at these higher pressures (see Table 2). Note: standstill pressure on some systems (e.g., cascade systems) is higher than the maximum rated suction pressure, requiring the need for a pressure-relief valve. This pressure-relief valve will discharge in the event of a fault, such as a power failure.

Table 2: R-744 standstill and typical system operating pressures

To ensure the pressure does not rise to the relief pressure in the event of a power failure or sudden system shutdown, these systems also can be fitted with a small auxiliary cooling system. This typically runs on an uninterruptable power supply and will switch on when the pressure rises above a designated point — which is lower than the maximum allowable pressure relief valve (PRV) setting but higher than the normal operating pressure. The auxiliary cooling system is sized to remove enough heat to keep the standstill pressure below the PRV setting of the flash tank (aka receiver). It also utilizes a series of check valves to protect the low side of a system.

Care must be taken when charging R-744 systems. The maximum operating pressure of some systems (such as cascade systems and parts of booster systems) is normally below the R-744 cylinder pressure. These systems must be charged slowly and carefully to prevent pressure-relief valves from discharging.

- Trapped liquid

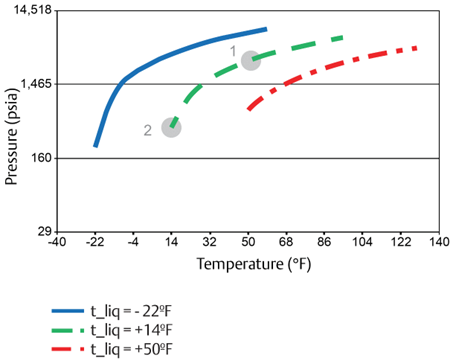

The coefficient of expansion for R-744 is significantly higher than legacy refrigerants. The practical impact of this on liquid R-744 trapped between closed valves is shown in Figure 1.

Figure 1: Relationship between temperature and pressure of trapped liquid R744

Source: Danish Technological Institute

This example shows the effect of a 36 °F (20 °C) temperature rise on liquid that is trapped at an initial temperature of 14 °F (-10 °C). The pressure will increase from 638 psig (44 bar) — point 2, Figure 1 — to approximately 3,480 psig (240 bar) — point 1, Figure 1. This condition could potentially occur in any R-744 liquid line. As a rule of thumb, trapped R-744 liquid will increase in pressure by 145 psig (10 bar) for every 1.8 °F (1 °C) temperature increase.

Simply put, the pressure of trapped liquid refrigerant always increases, but the pressure increase of R-744 is much greater than legacy refrigerants. This is exacerbated by the potential to trap R-744 at low temperatures and hence for the liquid temperature to rise more than other refrigerants.

CO2 refrigeration systems should be fitted with pressure-relief protection wherever liquid could be trapped, either during operation or servicing. Methods of providing this protection will be covered in an upcoming blog on the design of R-744 systems.

- Dry ice

Dry ice (i.e., solid R-744) is formed when R-744 pressure and temperature are reduced to below the triple point (60.9 psig [4.2 bar; -68.8 °F [-56 °C]). In a properly designed and functioning refrigeration system, this will not occur. Dry ice can occur when:

- A pressure-relief valve discharges if it is venting vapor R-744

- Venting R-744 during service (component change or replacement, for example)

- Charging with liquid when the system is below 60.9 psig (4.2 bar), e.g., an evacuated system

- Anytime internal system pressure accidently drops below 60.9 psig

Dry ice does not expand when it is formed, but it will become gas as it absorbs heat (e.g., from ambient temperatures). If dry ice is trapped within the system, it will absorb heat from the surroundings, start sublimating and turn into gas — which will result in a significant pressure increase.

Because the formation of dry ice can block vent lines, care must be taken to ensure that this cannot occur:

- Appropriate pressure-relief valves should be used.

- When R-744 is vented from a system during service, it should be vented as a liquid, and the pressure in the system should be monitored closely. R-744 should always be vented outside a building, safely away from the public or any occupied spaces.

- Freeze burns

The surface temperature of dry ice is -109.3 °F (-78.5 °C). Because physical contact with solid or liquid R-744 will cause freeze burns, care should be taken during servicing and handling. Protective gloves and goggles should always be worn when working with R-744.

The next blog post in this CO2 as a Refrigerant series will compare R-744 to both traditional and new refrigerants.

CO2 as a Refrigerant — Criteria for Choosing Refrigerants

by Andre Patenaude | Efficiency & Refrigerant Regulations, Refrigerants

This is post two of CO2 as a Refrigerant, a blog series covering the fundamental considerations...

CO2 as a Refrigerant – Properties of R-744

by Andre Patenaude | Efficiency, Efficiency & Refrigerant Regulations, Refrigerants

This is post three of CO2 as a Refrigerant, a blog series covering the fundamental considerations...

CO2 as a Refrigerant – Comparison of R-744 with Other Refrigerants

by Andre Patenaude | Efficiency, Efficiency & Refrigerant Regulations, Refrigerants

In post six of our CO2 as a Refrigerant blog series, I will compare CO2 to traditional and...

The post CO2 as a Refrigerant – Five Potential Hazards of R-744 appeared first on Copeland E360 Blog.