CO₂ as a Refrigerant – Introduction to CO₂ Booster Operation

This is post four of CO2 as a Refrigerant, a blog series covering the fundamental considerations and characteristics of CO2 as a refrigerant (R-744).

Depending on the climate, many R-744 booster systems operate above the critical point in supercritical mode) for a significant percentage of time annually. However, this is not a cause for concern, as the system is designed with these needs in.

Consider the following operating characteristics of a CO2 booster system compared to a traditional HFC system:

- Systems run in subcritical mode when the condensing temperature is below 87.8 °F (31 °C).

- Systems run in supercritical mode when the gas cooler exit temperature is above 87.8 °F (31 °C) and pressure is above 1,055.9 psig (72.8 bar).

- HFC systems always run subcritically because the condensing temperature never exceeds the critical temperature — which in the case of R-404A, is 162 °F (72 °C).

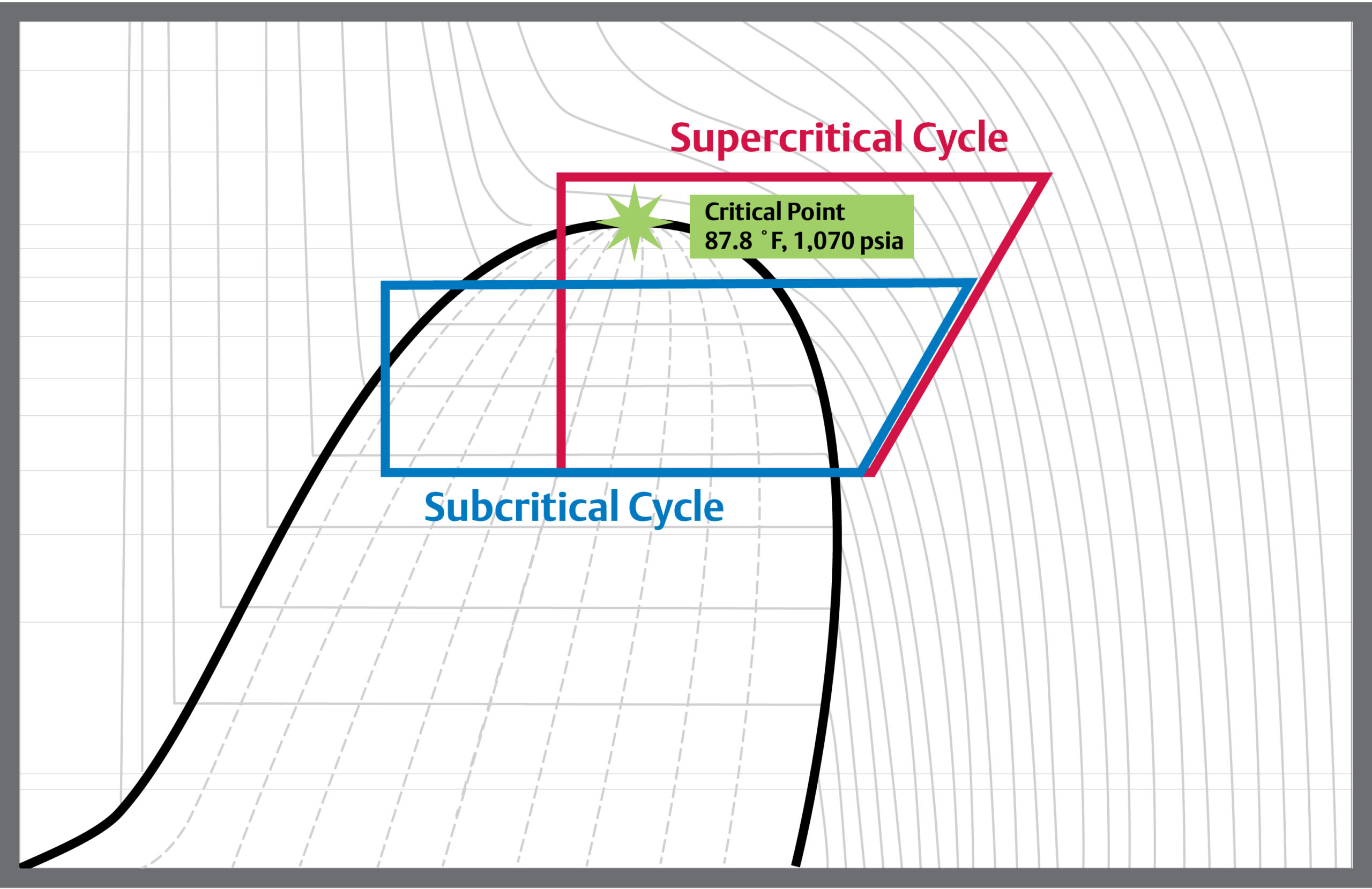

The pressure enthalpy chart in Figure 1 shows an example of a simple R-744 system operating subcritically at lower ambient temperatures and supercritically at higher ambient temperatures. The chart shows that the cooling capacity at the evaporator is significantly less for supercritical operation.

Figure 1: R-744 pressure enthalpy chart showing subcritical and supercritical modes of operation

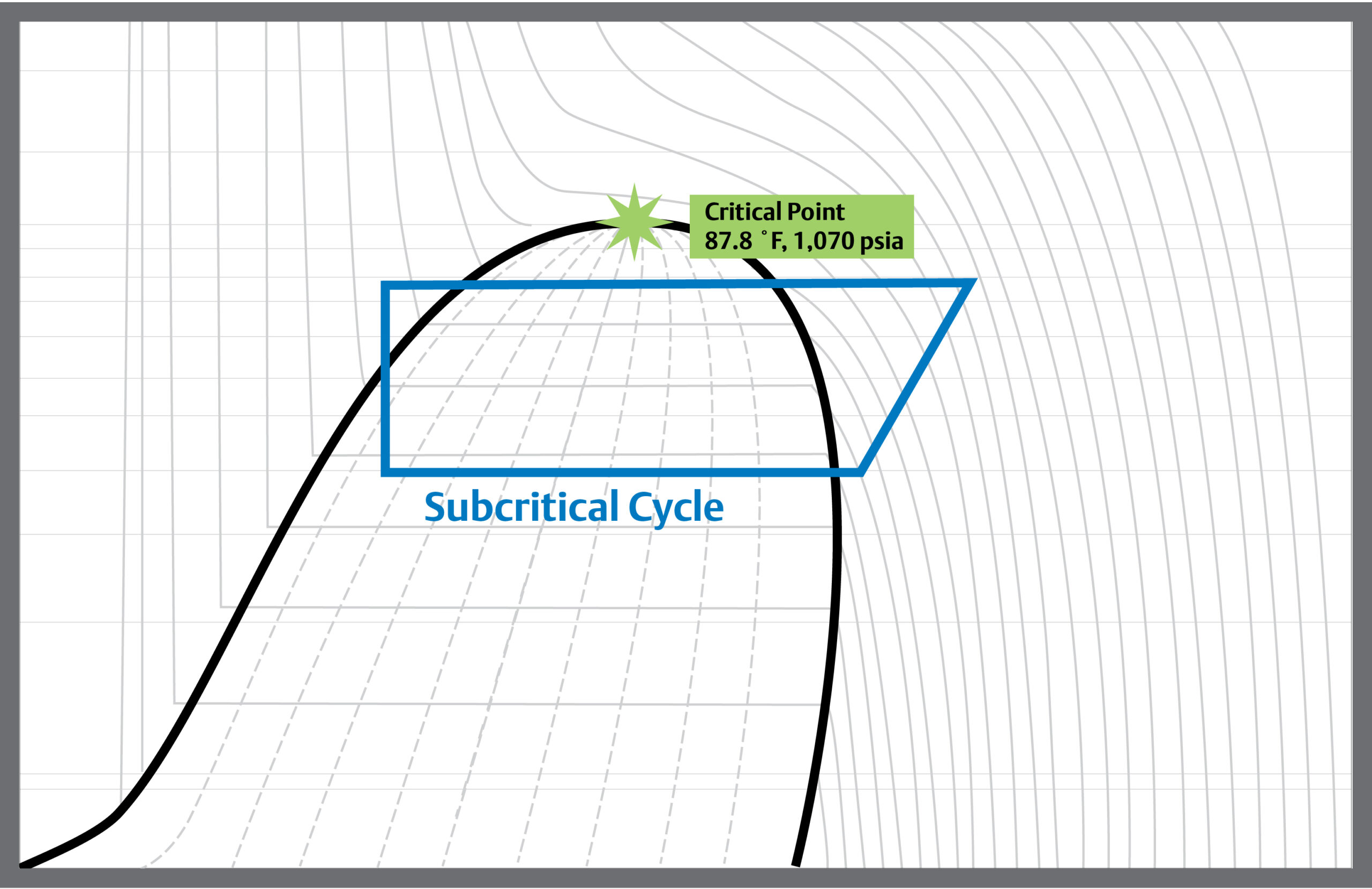

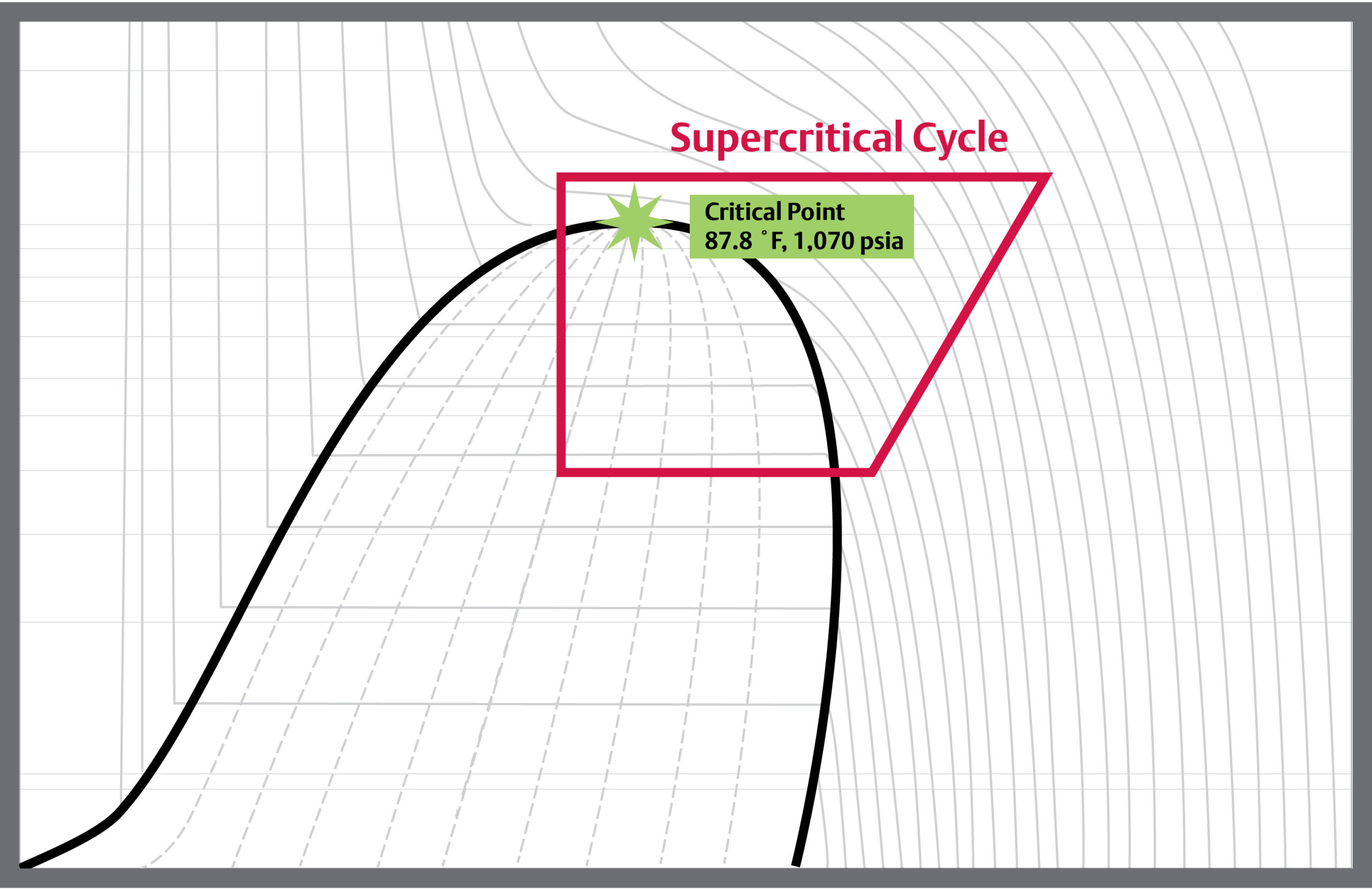

In climates or seasons with warmer days and cooler nights, a CO2 booster system will transition from subcritical to supercritical modes as the ambient temperature changes (see individual enthalpy diagrams in

Figure 2). These systems have historically been referred to as transcritical booster systems, due to the transition that takes place between subcritical and supercritical modes.

Figure 2: In warm ambient temperatures, a CO2 system will transition from subcritical to supercritical modes.

An efficiency drop also occurs with HFC systems when the ambient temperature increases, but the change is not as dramatic as it is when R-744 transitions from subcritical to supercritical operation.

It is important to exercise an appropriate control of the high side (gas cooler and/or condenser) pressure to optimize the cooling capacity and energy efficiency when a CO2 system runs in supercritical mode. For example, increasing the high side pressure will increase the cooling capacity — at the expense of increasing compressor energy consumption — when operating in supercritical mode (i.e., above CO2’s critical point).

Relative comparisons to legacy HFC refrigerants

Because CO2’s low critical point temperature requires unique system design strategies — such as the need for managing a CO2 system during supercritical operation — simple comparisons between R-744 and other refrigerants can be misleading and difficult to make.

Theoretical comparisons between R-744 and common HFC refrigerants are summarized in the list below.

- R-744 compares reasonably well with HFC systems when running in subcritical mode at low condensing temperatures. But the comparison of a basic system architecture is less favorable at higher condensing temperatures and when running in supercritical mode.

- The high suction pressure and gas density of R-744 result in very good evaporator performance. In like-for-like systems, the evaporator temperature of an R-744 system would be higher than for an HFC equivalent.

- The index of compression is very high for R-744, so the discharge temperature is higher than in HFC systems. This can improve heat reclamation potential in retail systems during supercritical operation, although the requirement for heat in the summer is less than when may be needed in the winter.

- The density of R-744 results in very high volumetric capacity. This reduces the required compressor displacement, although the motor size would be similar to those required for HFC refrigerants.

- The required suction pipe cross-section area is in proportion to the volumetric capacity. For R-744, the diameter of the suction line is approximately half that required for R-404A.

- When comparing R-744 to R-404A at 20 °F (-6.7 °C) saturated suction temperature (SST) and 90 °F (32.2 °C) ambient, the differential pressure from suction to discharge is approximately five times higher for R-744. This has led to significant compressor design changes to handle the higher bearing loads.

The next topic in this CO2 as a Refrigerant blog series will cover the potential hazards of R-744, compare them to other refrigerants (both traditional and new), and weigh its relative advantages and disadvantages.

CO2 as a Refrigerant — Criteria for Choosing Refrigerants

by Andre Patenaude | Efficiency & Refrigerant Regulations, Refrigerants

This is post two of CO2 as a Refrigerant, a blog series covering the fundamental considerations...

CO2 as a Refrigerant – Properties of R-744

by Andre Patenaude | Efficiency, Efficiency & Refrigerant Regulations, Refrigerants

This is post three of CO2 as a Refrigerant, a blog series covering the fundamental considerations...

CO2 as a Refrigerant – Comparison of R-744 with Other Refrigerants

by Andre Patenaude | Efficiency, Efficiency & Refrigerant Regulations, Refrigerants

In post six of our CO2 as a Refrigerant blog series, I will compare CO2 to traditional and...

The post CO2 as a Refrigerant – Introduction to CO2 Booster Operation appeared first on Copeland E360 Blog.