Understanding A2L refrigerant fundamentals — new blog and video series

A2L refrigerants are a new and relatively unknown commodity in the U.S. commercial refrigeration and air conditioning (AC) sectors. With the stage set for wider A2L adoption in the coming years, many stakeholders have a variety of questions and concerns that need to be addressed. In a new video and blog series, A2L Fundamentals, Joe Summers, senior product manager of Emerson’s Commercial & Residential Solutions Business and I set out to explain the drivers behind the emergence of A2L refrigerants and discuss their safe application. This introductory blog will provide an overview of the regulatory landscape that’s paving the way for A2L adoption. Please visit our content hub to view the video series.

As the hydrofluorocarbon (HFC) refrigerant phasedown progresses rapidly around the globe and in the U.S., the retail supply chain is transitioning to the next generation of refrigerant alternatives with lower global warming potential (GWP). Synthetic A2L refrigerants are among the leading emerging candidates capable of achieving the necessary GWP reductions.

A2L refrigerants: Classification and composition

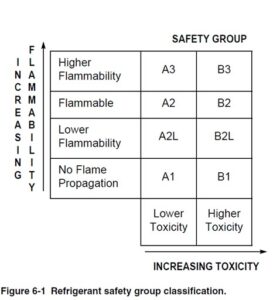

A2L is class of refrigerants that have a lower toxicity and lower flammability rating (aka mildly flammable) from the ASHRAE 34 standard. Refrigerant safety classifications are designated with an alpha-numeric character shorthand. The first letter in a refrigerant classification is its toxicity rating, followed by a number to indicate its flammability rating. An additional class delineates flammable refrigerants that burn very slowly, indicated by the third letter in the sequence: L. Thus, A2L is defined as:

- A = lower toxicity

- 2L = lower flammability

A2L refrigerants are composed of a variety of chemical compositions, including those with high hydrofluoroolefin (HFO) content; pure HFOs; pure HFCs; and blends of multiple components. HFOs were introduced to provide a combination of favorable environmental and performance characteristics — offering zero ozone depletion potential (ODP) and low-GWP levels below global regulatory thresholds of 300 and 150. Some A2Ls are based on HFO blends to provide specific GWP and performance characteristics. Common HFOs that are already in use in AC applications include 1234yf and 1234ze.

Path to regulatory approval

In many countries and/or regions around the world, A2L refrigerants are already approved for use in commercial refrigeration equipment, as well as AC and process chiller applications. The approval process is underway in the U.S.; governing bodies and industry organizations are working to pass legislation based on recently updated safety standards that would allow for the broader use of A2Ls.

Currently, the Environmental Protection Agency (EPA) is considering many applications and specific end uses across a spectrum of commercial refrigeration, HVAC, transport and industrial sectors. Its recently proposed HFC Technology Transition rule sets GWP limits of 150 and 300 in commercial refrigeration equipment, which would be likely candidates for the use of A2Ls. The EPA is also working on a new proposal under its Significant New Alternatives Policy (SNAP) program that would approve the use of A2L refrigerants and increase R-290 charge limits in commercial refrigeration equipment. A2Ls would not only be allowed in much higher charges than R-290, but would also be applicable across a much wider range of equipment, including both self-contained and field-erected systems. The proposed SNAP Rule 26 for A2Ls in commercial refrigeration equipment is expected to be announced in the next few months.

The EPA’s HFC Technology Transition proposal also sets new GWP limits for residential AC and process chiller sectors, calling for a 700 GWP limit which is slightly lower than the 750 GWP recommendation proposed by industry stakeholders. EPA SNAP rules 23 and 25 have already listed some A2L refrigerants as acceptable for use in AC and chiller applications, respectively.

Building codes that regulate refrigerants — including the use of mildly flammable A2Ls and higher charges of R-290 — must also be defined within each state. To date, 18 states have updated their building codes to support the safe use of A2Ls, and the industry is actively educating the remaining states on the need to begin the update process. Ideally, the goal would be to have all 50 states’ building codes updated by 2025.

The next blog in this series will take a closer look at the standards governing the safe use of A2Ls in commercial refrigeration equipment. To learn more about A2Ls, please view our A2L Fundamentals blog series.

Evaluating the ROI of Supermarket Sustainability Efforts

by Andre Patenaude | Cold Chain

The spectrum of supermarket sustainability concerns has expanded significantly in recent years. As...

Seven Keys to Demystifying CO2 Refrigeration

by Andre Patenaude | Cold Chain

The U.S. commercial refrigeration market is poised for a surge in the use of CO2 (R-744) as a...

Tools for Delivering Perishable Food Freshness This Holiday Season

by Doug Thurston | Cold Chain

More than any time of year, food is a central attraction of the holiday season. Sharing, preparing...

The post Understanding A2L Refrigerant Fundamentals — New Blog and Video Series appeared first on Emerson E360 Blog.